Latest topics

Information on Printing Pottery

Page 1 of 1

Information on Printing Pottery

Information on Printing Pottery

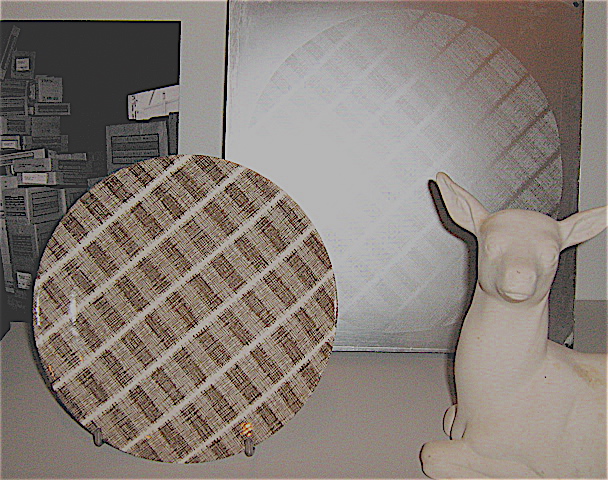

I noticed this Lithographic printing plate with a repetitive design with the finished printed plate in front at the recent exhibition. The Litho Plate is larger than the Crown Lynn plate shown so would be suitable for a range of plate sizes using the same design. This could well have been used with the Murray-Curvex printing machine.

The Litho Plate above would have been first inked in the colour chosen and then the design transferred to a compressible, silicone- rubber half ball which was then pressed onto the bisque fired plate to print the design.

This method allowed a single operator to decorate plates at a much faster rate than was possible by transfer application. I remember seeing this process operating during a visit to Crown Lynn in the 1970's, didn't take a lot of notice as I was just passing on the way to another department but was impressed with the flow of product with a single operator.

Multiple colours were possible although the example shown used multiple tones of a single colour.

The Litho method of printing enables half-tones to be printed using a very fine screen and therefore a much more detailed design than is possible by the Bat or rubber stamp method. The inking process is more complex than I have indicated but well understood in the printing world.The transfers used extensively to decorate pottery are generally produced using the Lithographic printing method.

According to Monk (p65) the first Murray-Curvex arrived at CL in 1959 , only four years after the patents were registered and eventually were able to print up to three colours at the rate of up to 3500 pieces per 8 hour shift on flatware and shallow bowls, a marked advance on the hand application of transfers.

There is also mention of a Malkin printing machine being used at Crown Lynn but I have not been able to find any useful information on this make,I suspect it may have been of American manufacture.

For more detailed information on the decorating and printing of pottery there is a useful site at

http://www.pottersfriend.co.uk/p.php?page=ColourDecoration

By scrolling down you will reach a detailed section on the various methods used.

Last edited by Jonno on Mon 30 Jan - 22:07; edited 1 time in total (Reason for editing : typo error corrected)

Jonno- Number of posts : 662

Location : Milford,Auckland

Registration date : 2011-05-13

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

» Glenn Beattie

» Rancich/Silva Shape 58

» NOT a Sherwood Pottery Galleon, as Made in Japan

» Minna Bondy

» Jan Gillespie

» Studio Ceramics wall swan...

» Hamilton Boys High and Old Folks Assoc. Hamilton Badgeware

» Studio Ceramics Villagio and Porto